Description of the infrastructure:

The Laser Machining Laboratory (LS-LAB-UCA) of the Department of Condensed Matter Physics/IMEYMAT of the University of Cádiz, is a laser processing laboratory that is equipped with a state-of-the-art laser material processing station, called NANO-GLAS laser station. The NANOGLAS laser station is a laser processing station with adjustable pulse duration, from 190 femtoseconds (fs) to 400 nanoseconds (ns), and high repetition frequency (up to one megahertz (MHz)), which is specifically designed for the generation colloidal dispersion of nanoparticles, the manufacture of nanostructures and/or nanostructured materials, the surface nano-texturing of massive materials, the laser machining of materials and/or the laser cutting of materials.

The main technological feature of the NANO-GLAS laser system is its ability to generate high-power laser pulses (up to 50 W), with different pulse durations (from 190 femtoseconds (fs) to 400 nanoseconds (ns)), with high repetition frequency (from a single laser pulse to one megahertz (MHz)), and with different wavelengths (1030 ± 10 nm (Infrared), 515 ± 10 nm (green), and 343 ± 10 nm (ultraviolet)).

To achieve this goal, this laser installation integrates four pulsed laser sources integrated into the same cabin with total protection against laser radiation:

- A first ultrashort pulse laser source, capable of emitting high power infrared pulses (maximum nominal power ≥ 50 W), with adjustable duration between 10 picoseconds (ps) to 190 femtoseconds (fs), repetition frequency adjustable from a single pulse at 1 MHz and triple laser emission at wavelengths of 1030 ± 10 nm (Infrared), 515 ± 10 nm (green), and 343 ± 10 nm (ultraviolet).

- A second laser source capable of emitting high-power infrared pulses (maximum nominal power ≥ 30 W) with emission in the infrared range, repetition frequency from 2 kHz to one megahertz, and modulable pulse duration from 100 picoseconds to 5 nanoseconds.

- A third nanosecond pulsed laser source capable of emitting high-power infrared light pulses (maximum nominal power ≥ 50 W) with duration and repetition frequency of the laser pulse adjustable from 4 ns to 200 ns and from 2 KHz to 1 MHz, respectively.

- A fourth nanosecond pulsed laser source (30 ns), with emission in the visible range (532 nm), minimum power of 15 W, and repetition frequency between a single pulse and 300 KHz. iv) And a fifth nanosecond pulsed laser source (25 ns), with emission in the ultraviolet (355 nm), repetition frequency between 1 pulse and 500 kHz and minimum power of 6 W.

In addition, this installation is equipped with different galvanometric heads with f-Theta focal lens, mounted on a motorized platform for positioning on the z axis (minimum height variation of 200 mm), which allow the direction of the laser beams to carry out “ scans” on the surface of the sample to be treated, where the position of the laser beam varies in “x”, “y” and “z” with respect to said surface, allowing precise control of the focal length, the scanning speed and the number of laser pulses fired at the same point on the surface of the irradiated material. On the other hand, this installation has a system of motorized linear X-Y axes for positioning (maximum travel of 200 mm x 200 mm), with great precision, of the laser beam with respect to the surface of the sample. This makes it possible to combine, with a moving sample, the sweep produced by the galvanometric head with the movement of the X-Y positioning axes, increasing the total processing area of the sample surface with respect to that which can be scanned only with the galvanometric head.

On the other hand, it is important to point out that this installation has a measurement and analysis system integrated inside the working chamber of the NANO-GLAS laser system, which allows pre-analysis and post-analysis in situ of the surface of the samples, which are going to be processed by laser, and/or the mechanism for generating nanoparticles and/or nanostructures. This system is made up of:

- An optical vision and analysis head with triple acquisition technology: confocal scanning, optical interferometry and focus variation.

- A vacuum system for the laser processing of materials in different work environments (gases and/or liquids), which is equipped with an ultrafast CMOS camera using iCCD technology with nanosecond temporal resolution, which allows the analysis of space-time interaction between the laser beam and the plasma plume, which is generated by the ejection of material stripped from the surface of laser-irradiated samples.

- A tunable, motorized, high-resolution spectrograph with a diffraction grating of 1200 l/mm, which allows to analyze the chemical composition of the material cloud ejected from the surface of the sample subjected to machining/texturing/laser ablation.

Given that the NANO-GLAS laser installation integrates several pulsed laser sources and analysis systems in the same station, this installation has:

- A series of opto-mechanical sets automated by software, necessary for the guidance and alignment of all the laser beams to the processing heads.

- A viewing system of the sample area to be irradiated.

- A system for measuring the laser energy that reaches the sample to be treated and

- A control software that allows simultaneous control of the working parameters of the laser sources, the optical movement system of the laser beams and the mechanical positioning system of the sample. All these elements are integrated in a Class I protection enclosure against laser radiation.

Services currently offered and possible applications in other fields:

1.- Surface treatment of massive materials of different nature by surface laser texturing with high-power laser pulses, adjustable frequency from a single pulse to one megahertz, and adjustable pulse width between 190 femtoseconds and 400 nanoseconds. Some of the applications of the laser texturing process, which are currently being developed at the NANOGLAS facility, are the following:

- Generation of materials with nano/microstructured surfaces that present adequate behavior control with respect to humidification. This type of surface laser processing work can be applied to promote the adhesion and proliferation of living organisms such as cells on surfaces of prostheses and surgical implants or, on the contrary, to prevent the adhesion and formation of biofilms of bacteria on surgical devices. On the other hand, this type of surface laser processing can also be used to try to generate superhydrophobic surfaces with self-cleaning and anti-freeze properties, etc.

- Nanometric-scale optical functionalization of various materials of interest in the field of photonics through the generation of periodic structures induced by laser irradiation (LIPSS, for its acronym in English), which modify the behavior of the material with respect to light absorption depending on the thickness and periodicity of these periodic structures. This type of processing can be used to try to generate permanently colored surfaces with applications in the automotive industry, aeronautics, construction, decoration, etc.

- . Conservation of artistic and cultural heritage by cleaning the surface of works of art (paintings, documents, paleontological remains, ceramics, etc.) with ultrashort laser pulses, which remove either layers of dirt or layers of material without artistic interest

- Surface nanostructuring of conductive metallic materials to generate surfaces with controlled roughness, capable of trapping electrons and generating surfaces with low secondary emission for high-power radio frequency (RF) devices on board satellites.

2-High-precision laser micromachining of metals, steels, plastic parts and ceramic materials using ultrashort laser pulses (femto and nanoseconds). This micromachining process can be used, for example, for the generation of scaffolds in polymeric materials, alloys for surgical use and/or ceramics with applications in regenerative medicine; as well as for the manufacture of solid oxide anodes for fuel cells.

3-Printing drawings and/or patterns on metals, woods, ceramics, plastics, glasses, etc.

4-Direct synthesis of colloidal nanoparticles with potential applications in medicine, the environment, catalysis and/or energy by means of laser ablation of metallic targets in liquid. The method of generating nanoparticles by laser ablation in liquid can be used, for example, to synthesize nanofluids of different nature, such as:

- Nanofluids composed of hybrid nanoparticles with functionalities in Magnetic Resonance Imaging and X-Ray imaging. AND

- Nanofluids formed by hybrid nanoparticles with functionalities in Magnetic Resonance Imaging and Optical Imaging.

- III. Nanofluids formed by nanoparticles with shape memory properties and superelasticity or with ferromagnetic shape properties.

- Nanofluids made up of metallic nanoparticles with reducing properties for use in catalysis or environmental cleaning.

- Nanofluids formed by nanoparticles with high thermal conductivity and heat transfer capacity for their application as cooling liquids or as thermal fluids with applications in petrochemicals or power plants.

- Nanofluids formed by nanoparticles with catalytic properties for their application in the development of new renewable energy sources.

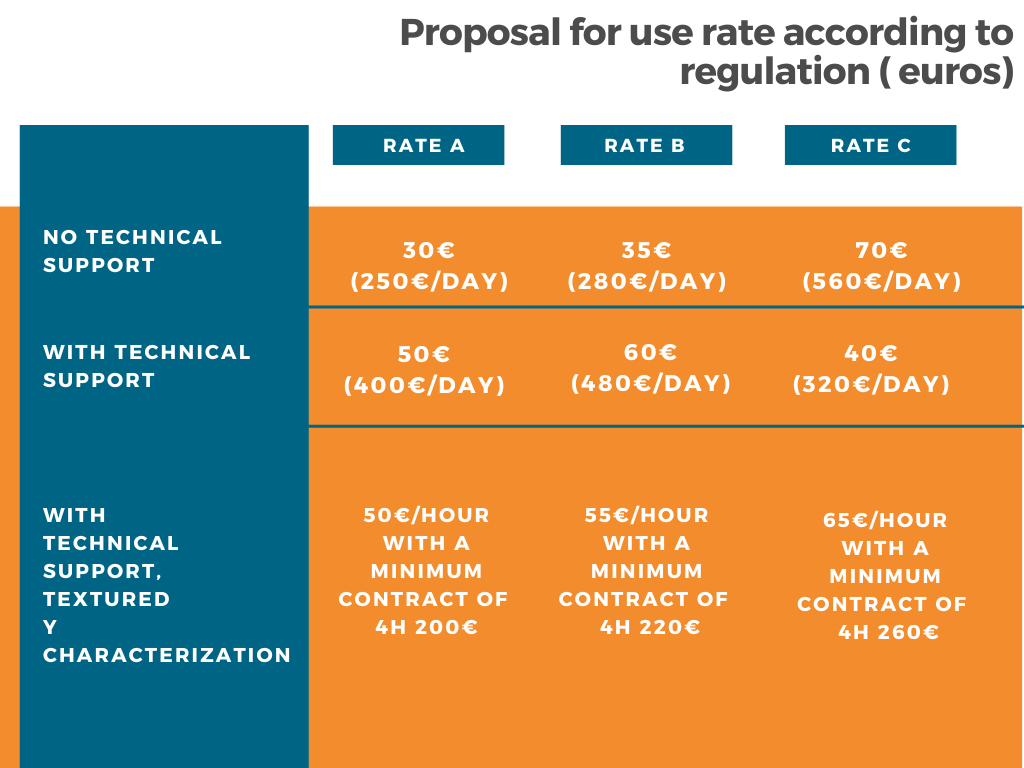

Rates

Rates for technological support work and carrying out laser processing experiments without signing an R&D contract or without signing a scientific collaboration agreement in R&D&I projects obtained in competitive public calls:

Rate A

– Hour of use of the equipment with technical support from the person in charge of the installation: €50 (€400/day).

– Hour of use of the equipment without technical support from the person in charge of the installation: €30 (€240/day).

– Hour of use of the equipment with technical support from the person in charge of the installation, including the laser texturing process of the material and the characterization of the textured surface. €50. The minimum package to pay in this case will be 4 hours (200 €).

Rate B

– Hour of use of the equipment with technical support from the person in charge of the installation: €60 (€480/day).

– Hour of use of the equipment without technical support from the person in charge of the installation: €35 (€280/day).

– Hour of use of the equipment with technical support from the person in charge of the installation, including the laser texturing process of the material and the characterization of the textured surface. €55. The minimum package to pay in this case will be 4 hours (220 €).

Rate C

– Hour of use of the equipment with technical support from the person in charge of the installation: €70 (€560/day).

– Hour of use of the equipment without technical support from the person in charge of the installation: €40 (€320/day).

– Hour of use of the equipment with technical support from the person in charge of the installation, including the laser texturing process of the material and the characterization of the textured surface. €65. The minimum package to pay in this case will be 4 hours (260 €).

In the event that the performance of these technical support and laser processing of materials lasts for several days, the following discounts will be applied:

– Two days of work: 10% discount

– Three days of work: 20%

– Five or more days of work: 30%

Is it necessary to use a technician: yes. Have a technician: no

Observations

– 1. In those services that require the use of special consumables or those not available in the Laser Machining Laboratory (LS-LAB-UCA) of the Department of Physics of Condensed Matter-IMEYMAT, the cost of this consumable will be borne by the user, who has contracted the service.

– 2. The costs of sending and returning the materials, which are to be subjected to laser processing, will be assumed by the user requesting the service.

– 3. The protocol for contracting a service at the NANO-GLAs laser station is the next:

I. Request for this service to the technical scientific manager of this infrastructure, Dr. Oscar Bomati, by telephone or email.

II, Sending via email the details of the service to be carried out with information on the material to be processed and a description of the characteristics that you want the materials to present, which are going to be textured, mechanized and/or generated by laser processing, in order to determine if the NANOGLAS laser installation has the necessary capacity to perform this service.

III. Evaluation of the request for the service to be contracted by the scientific-technical committee of this facility. This committee is made up of Dr. Oscar Bomatí Miguel and Dr. Eduardo Blanco Ollero.

IV. Communication to the possible user of the service, where the acceptance or withdrawal for the performance of the requested laser processing service will be indicated.

V. In the event that the performance of the requested service is accepted, the potential user will be contacted to schedule this service in the work calendar of the NANO-GLAS laser installation, attending, as far as possible, to the temporary needs of the user. customer.

VI. Reception of the samples, which will be subject to the laser processing process.

VII. Carrying out technical support services and laser processing experiments

VII. Delivery of samples subjected to laser processing

IX. Billing and collection of the requested service.