Description of the infrastructure:

Instrument for the three-dimensional scanning of objects with sufficient precision for metrology applications. Designed for engineering professionals looking for an affordable and reliable way to improve product development, shorten time to market, and reduce development costs. With dynamic reference (requires the use of positioning targets in the form of stickers), both the scanner and the part can move freely during the scan, obtaining an accurate and high quality scan. Accuracy: 0.040mm. Volumetric accuracy: 0.020 + 0.100 mm / m. Measurement speed 480,000 measurements / s. 7 red transverse lasers. Scan area 275 x 250 mm. Part size range (recommended) 0.1 – 4 m. Output formats .dae, .fbx, .ma, .obj, .ply, .stl, .txt, .wrl, .x3d, .x3dz, .zpr, .3mf. Weight 0.85kg (scanner) + 1.5kg (laptop).

Services currently offered and possible applications in other fields:

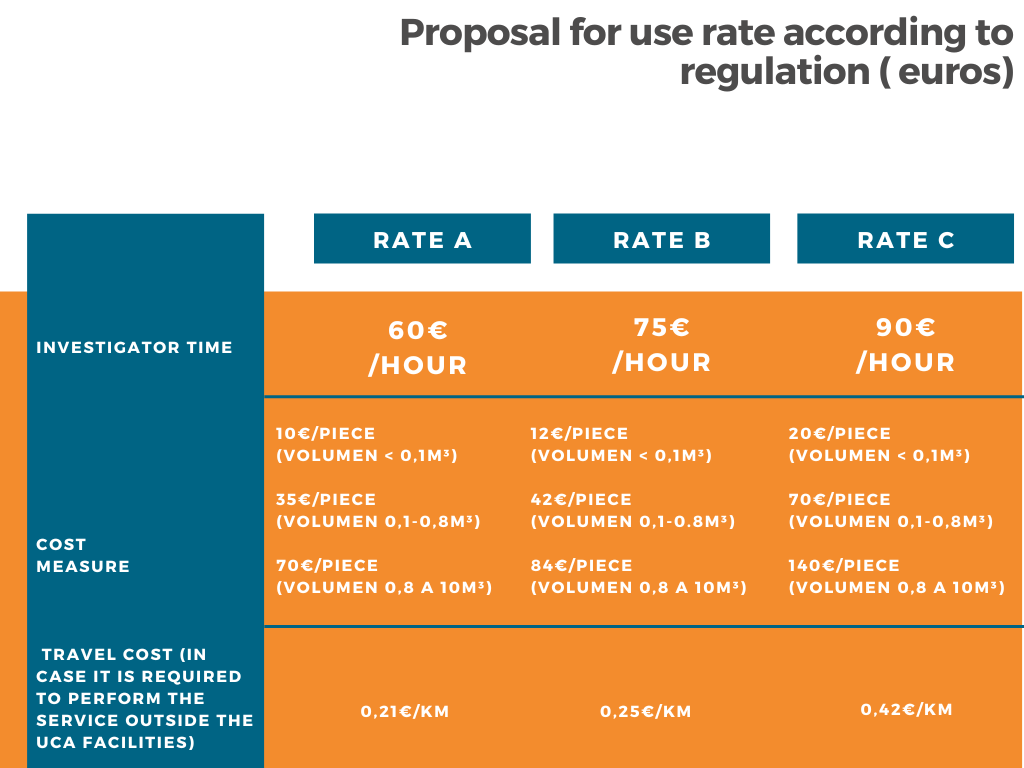

Capture accurate and repeatable 3D measurements of any object, including those with a complex surface. The objects to be scanned must be sent to the base location of the scanner, although ‘in situ’ scanning outside the University facilities could be considered, taking into account the cost of travel (technical staff allowance and mileage).

Is it necessary to use a technician: yes. Have a technician: yes.

Observations

Justification of the fees: the fees are linked to the cost of acquisition and maintenance of the equipment and its peripherals. The hours of use will depend on the time required for the part to be scanned to record all the information on its surfaces, and on the level of detail and precision required.