Description of the infrastructure:

Instrument for the three-dimensional scanning of objects with sufficient precision for metrology applications. Portable CMM optical scanner designed for the metrology and manufacturing professionals. It is not affected by vibrations in the production area, nor by the movement of parts or the instability of the environment. Designed to perform in both the metrology lab and production area, it is optimized to perform metrology grade measurements and 3D surface inspections on a wide variety of parts, regardless of size, material, finish or complexity. Polling capability (optional) that can be combined with 3D scanning. ISO 17025 accredited and compliant with VDI / VDE 2634 part 3. Accuracy: 0.025 mm. Volumetric accuracy: 0.044 + 0.015 mm / m. Measurement speed 1,800,000 measurements / s. 15 blue transverse lasers, ideal for shiny and reflective surfaces. Scanning area 310 x 350 mm. Part size range (recommended) 0.2 – 6 m. Output formats .dae, .fbx, .ma, .obj, .stl, .txt, .wrl, .x3d, .zpr, .3mf.

Services currently offered and possible applications in other fields:

Capture accurate and repeatable 3D measurements of any object, including complex surfaces and shiny surfaces. The objects to be scanned must be sent to the base location of the scanner, although an ‘in situ’ scan could be considered outside the University facilities, taking into account the cost of travel (diet for technical staff and mileage).

Is it necessary to use a technician: yes. Have a technician: yes.

Observations

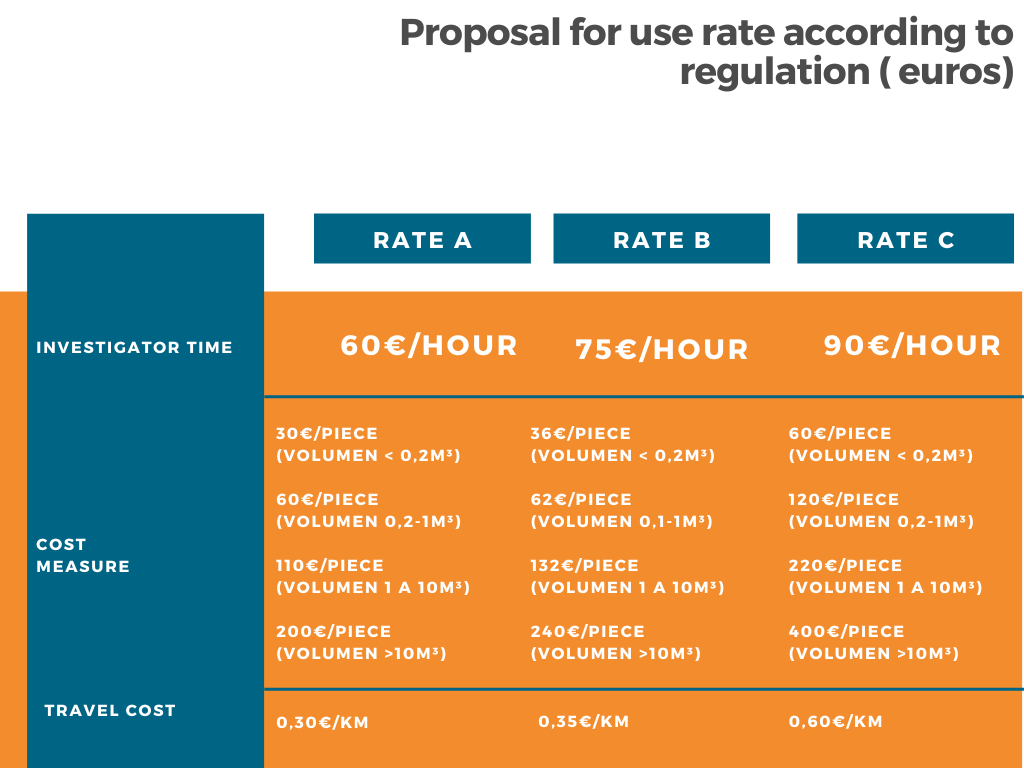

Justification of the fees: the fees are linked to the cost of acquisition and maintenance of the equipment, its peripherals and to deal with specialized software licenses. The hours of use will depend on the time required for the part to be scanned to record all the information on its surfaces, and the level of detail and precision required.