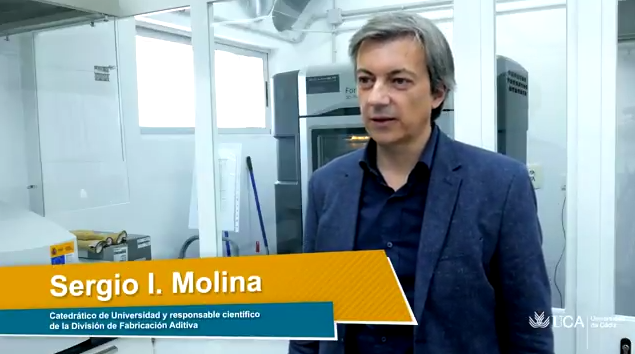

Sergio I. Molina, Full Professor and member of IMEYMAT, is the promoter and scientific responsible of the Division for Additive Manufacturing of the University of Cadiz.

This division manufactures prototypes and products through the successive superposition of layers of material from the information contained in a 3D digital file. For this purpose, various resources are used, such as polymer-based materials, binder injection, powder ink for color prototypes or photosensitive resins. This method of manufacture brings numerous advantages among which stand out the freedom in the design, the improvement of the functionality of the products, the lower cost of manufacture or the increase of the life cycle. Its scope of application is very wide, medicine, the development of materials and even naval or aerospace transport.

Next, you can see an interview conducted by the Unit of Scientific Culture and Innovation to our colleague Sergio I. Molina.